Contact us today on 086 8210557 or

email: info@ecowbs.ie

Know How

What makes BRUNNER so special?

➢ Clean Glass

The key factors influencing clean glass are construction, low pressure in the chimney, wood moisture, wood amount and operation.

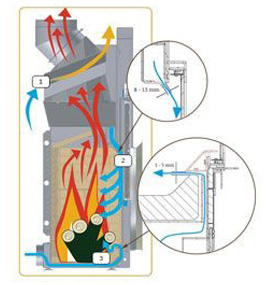

The construction

BRUNNER has designed the combustion air guide in such a manner that the inflowing air in front of the viewing glass reduces the accumulation of soot and dust. The door-profile and the pane construction prevent the protection shield of interferences due to leaks. The panes stay clean and soot-free. The pane-geometry has a major impact, too. Small, straight pane-formats remain clean for longer. In comparison two or three side glass constructions (Corner and Panorama fireplaces) with turbulent airflows in the corners have to be cleaned more frequently.

Chimney negative pressure

It is not possible to compensate too high or low negative chimney pressure with adjustable combustion air openings. Under these boundary conditions flow conditions can cause increased soot deposits.

In case of low negative pressure not only the combustion air cannot be sucked in sufficiently, but also the pane flushing air is blown in too weak. The air flows over the panes with an insufficient throw distance. In case of too high negative pressure the “suction” sucks the inflowing air at the top into the coupler area. As a result the flushing air cannot flow over the pane in order to fulfil its protective effect.

In both cases a turbulent and unstable combustion arouses, which results in the accumulation of unburned gas particles on the viewing glass. Consequently, the panes are filthy.

With technical measures it is possible to optimise these circumstances (i.e. Sissi flap for too high chimney negative pressure). Unfortunately unpredictable weather-related bad operating conditions can never be avoided and must be accepted as an exception.

Wood moisture, wood amount and operation

The fuel quality and quantity also has a large influence on clean panes. A basic condition is dry wood with residual moisture of under 20%. Furthermore required temperatures and airflows for flushing air can only be achieved when specific filling quantities are adhered. In case of too low temperatures in the combustion chamber heating gases condense on the cold panes. In this case they soot and fog-up.

During burn-off the intended operational mode is essential. If the device is used by different people we recommend the automatic combustion air system EAS/EOS. This system guarantees optimal combustion air guidance and helps to avoid operating errors.

➢ Easy door lifting and cleaning

➢ Control systems

A tile stove is just as good as the wood and proper operation. The most important thing is combustion air supply, adjusted most often manually. If one fails or forgets to adjust air supply as desired, it will lead to incomplete combustion, stained viewing glass, unpleasant odour, increased consumption of wood and finally – loss of energy collected eventually by accumulation stoves.

To prevent this from happening, we have our electronic control system EOS6. It's designed to ensure safe and more convenient operation of your fireplace or tile stove by automatic combustion control. The system is displaying all errors and faults immediately, preventing any potential defects or malfunction. In addition, through optimized combustion and significantly higher efficiency it helps to save money by reducing wood consumption.

➢ Quality and warranty

Quality

BRUNNER is a name for long-life products and best quality. Our aim is that you are satisfied as our customers and remain happy with your BRUNNER product for many years. Our products are made of best materials available on market and are manufactured 100% in Germany by skilled employees, who share the enjoyment and passion for BRUNNER products. This is our key to success.

Warranty

You receive two years product warranty from your stove setter, responsible for the installation and dimensioning of your fireplace or tile stove. But if your BRUNNER product fails as described in our warranty conditions, and the damage has nothing to do with normal wear and tear of certain parts, we offer a product warranty that goes far beyond the legal requirements regarding manufacturer's liability.

Register your product for optimal warranty support.

Fireplace Types

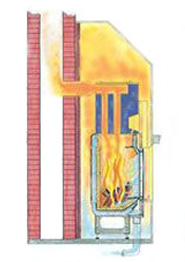

Warm air fireplace

... with a fitted steel plate shuttering

The hot combustion gas from the combustion chamber gets cooled

down in the steel cap and releases warm air.

This solution is ideal when

you need warm air in a small room within only

a few minutes.

Fireplace with boiler

... with an attached water heat exchanger

The hot fumes from

the combustion chamber stream the kettle body, which is fitted on top of

the combustion chamber.

This is the ideal solution

if you don't only want a fireplace effect but also wish to support your

central heating

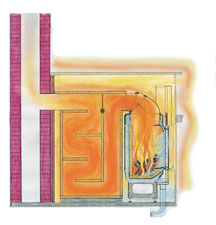

Accumulator fireplace

... with an adjoining, ceramic accumulator

The hot fumes from the combustion chamber accumulate to a hot core stream over a compact cast casing.

This is the best way of heating up storage like in a tile stove.

This is the ideal solution when you are planning on using a larger smokestack as a solution for radiation heating.

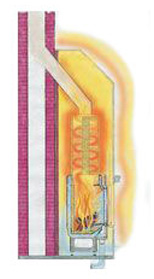

Accumulator fireplace

... with a fitted, ceramic accumulator

The hot fumes from the combustion chamber stream through the

storage which is fitted on top of the combustion camber.

This is the ideal solution

if high efficiency and a radiation heating is required on smallest area.

Where does the heat come from?

It's only about physics...

It starts with the energy and fuel value of dry wood which is stated at 4 kw/h per kg and the energy release process which is better known as the actual heating.

In the combustion chamber of the furnace you would normally burn between 4kg and 10kg of wood (16kW/h and 40kW/h per kg energy). Wood fibre changes into combustion gas and generates heat and warmth.

One part of the heat is produced in the combustion chamber of the tiled stove or the fireplace, and is thus emitted directly from the "epicenter". The heating gases, which emerge in the combustion chamber and have a temperature of approx. 800°C, contain the other great part of the energy.

By using different heat exchanging devices, the temperature is detracted from these energy amounts and can thus be used as heat. The smoke gases are cooled down fast in the ceramic stove system and are used as hot air for great heat outputs. When the heating gases are passed through a draught-canal of a mass capable of heat storage, this mass is heated up and emits a steady radiant heat for hours. Another possibility is to pass the heat gases through a vessel body which operates like a real heat exchanger in the furnace.

To use the knowledge of creating energy by using wood and combining this with all kinds of different types of systems for all individual needs is our supreme discipline. Only a perfectly aligned wood stove system for a stove or a fireplace can provide the desired well being.

All BRUNNER does is to build the best combustion chambers with specially aligned warmth systems. This is what makes BRUNNER so unique. They call this expertise - you will call it satisfaction.

How to store wood

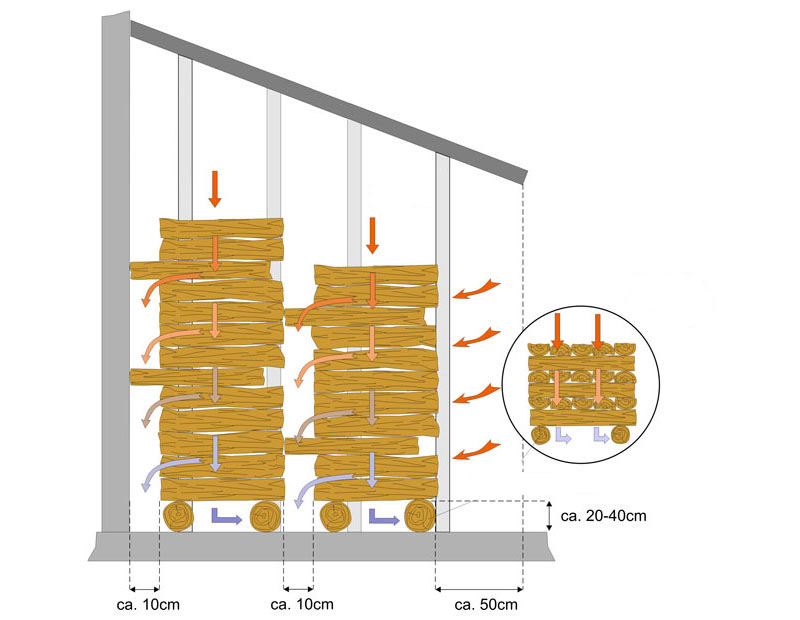

Firewood storage

How to store firewood the right way

• Store your firewood in a sunny and aerated area (south/west side)

• Make sure the ground is dry

• Store it with at least 15 cm distance to the ground

• By storing it cross piled it dries quicker

• Cover it with a rain shield as soon as it is dried

• When storing it make sure there is at least a gap of 10 cm between the wood and the building so the wood can aerate

• If possible keep the daily consumption near to the fireplace

Did you know?

In 4-12 months your firewood can be dried to 18 to 22%.

That means you can stack a one year supply of firewood in spring and use it in your next heating period.

Question & Answers

➢ The stove smells when it is heated for the first time.

During the first heating circles the different components heat up, oils and paint evaporate and harden. Although excellent paint and cleaning procedures were used, this cannot be avoided completely. Since the fireplace is not heated at full power right from the start but the heating is increased gradually, the smells will prevail for a while but eventually the intensity will decrease quickly. Make sure you air the room sufficiently. Before using the fireplace for the first time remove all stickers (instalment advice, article numbers).

➢ The stove smells after it has not been used for a long period.

During the resting period dust accumulated on the stove components. This “burns” when the stoves is activated. Clean the surfaces of the heating element, smoke pipes and heat exchanger before you start the stove. If the system is overloaded (too much flue gas) this can also cause smells.

➢ The glass ceramic window is dirty.

A certain amount of dirt cannot be avoided. Especially during the initial phase the burning is incomplete with condensation on the glass. A large amount of dirt indicates that the stove is not used properly. Possible faults: mostly too wet fuel or not enough combustion air supply.

➢ The stove burns hardly or doesn't even start.

In most cases this is due to chimney low pressure or not enough burning air supply. Short term solution: Start an attracting fire, open combustion air supply fully – open start up flap – smoke extractor if available on full power.

➢ The stove smells of burnt gas.

Heating gas is leaking. Check the sealing of the connecting pieces and the chimney flue. Make sure sufficient burning air supply is provided.

➢ What is a hot air tiled stove?

A type of tiled stove where the released energy from the burning phase is quickly turned into heating. Construction: A separate heating element made of cast is attached to the encasement with attached metallic heating surface. The room’s air which flows into the stove’s encasement through openings at the bottom is heated on the hot surfaces and evaporates – mostly through grills – into the room.

➢ How do I clean glass ceramic windows?

Use a damp (not wet) piece of paper. Clean persisting spots also with a damp piece of paper which was dipped into some wood ashes. Do not use cleansers or detergents. Such cleansers contain substances which eventually destroy the sealing.

➢ What properties does glass ceramic have?

It does not expand when heated and therefore does not build up any tension. Also if it cools off quickly it does not form any cuts or breaks. Glass ceramic can tolerate up to 700°C. On higher temperatures the glass turns milky and hazy. This hardly changes the resistance but it is no longer see-through.

➢ What are stove windows made of?

Stove windows are made of glass ceramic – similar to the glass ceramic cookers used in kitchens.

➢ What is a storage tiled stove/ masonry stove?

This is a tiled stove releasing the energy produced in the fire chamber in a retarded way for hours to the room. Heating is produced in a bricked chamber. The smoke gases pull through the heat store which works like a heat accumulator and consequently to release the heat on its surface as mild radiating heat. The fireplace builder determines the heat to be released by calculating the stove surface and the wall temperature. The storage capacity is influenced by the weight.

➢ I need new chamottes for my fireplace, where can I get them?

You are able to order your new chamottes directly from us, Eco Wood Burning Stoves.

Please contact us on 085 8210557 or email info@ecowbs.ie

➢ The burning chamber chamotte of our tiled stove has cuts. Do they need to be replaced?

Chamottes is a heat resistant material serving to protect the fireplace walls made of metal or cast. Individual cuts in the chamottes can happen and are not a reason to complain, because this is a natural procedure due to the strain the material is exposed to. The protective purpose still prevails and the stones don’t need to be exchanged. You have a right to complain and to ask for replacement only if the material dissolves in form of sand or in form of pieces and the protective function continues to decrease.

➢ Can fireplace inserts with a sliding door be used open?

In general you can operate fireplace inserts open the construction allows for it. Whether the open use of the fireplace is possible depends on the overall installation. Details are important here, such as chimney diameter, height of the chimney combustion air supply etc. For example, an open fireplace must be attached to a separate chimney, it is not possible to use the chimney for several purposes. The basis for decision in this respect is the chimney calculation the fireplace builder will make.

➢ Is it possible to use coal, coal bricks or wood bricks?

This type of fire is ideal for burning wood, but not for coal. Coal requires combustion air from below and needs the possibility to shake off the fire bed and to remove the ashes. This is why coal cannot be used. Apart from that, the firing system is designed for wood. However, wood bricks according to DIN 51731 size HP2 can be used any time.

➢ What is the difference between the nominal heat output and the burning heat output?

The nominal heat output is the heat transmitted to the room it is heating. The burning heat output is the heat released in the burning chamber by the fuel. Especially for fireplaces with major storage mediums where heat is generated after a short burning period, burning heat output and nominal heat output can be clearly different.

➢ When does a deflagration happen?

Wood decomposes when it is heated and turns into flammable gas. The gas mixes with the inflowing combustion air and burns with its typically long flame. This gas venting procedure can only be reduced i.e. stopped through cooling off and not by turning off the combustion air. Therefore if you cut off the combustion air during the normal burning, the “gas production” continues, the required combustion air is missing. The burning gas becomes a “critical mass” and start burning at the first contact with combustion air. This can lead to complete destruction of the fireplace and be hazardous for your life.

➢ Can the combustion air be lead through a supply air canal inside the chimney into the heating element?

Basically every chimney installation has to be calculated by an expert. This includes the flue gas deduction as well as the combustion air feeding. Based on our experience the combustion air inlet through a special canal in the chimney is a problem. When the chimney warms up it develops a natural flotation making the combustion air supply more difficult.

➢ Can I start a tiled stove immediately with full power?

No. Parts of the stove are loaded with plaster. The water contained there must evaporate slowly by means of moderate heat. If the heat is added to fast the amount of water vapour cannot be deducted sufficiently – malfunctions and damages to the construction parts will be the consequence. Your fireplace builder will tell you the right way to start.

Eco Wood Burning Stoves

Kieran Brennan,

Massford, Moneenroe, Castlecomer, Co. Kilkenny.

Mobile: 086 8210557

Email: info@ecowbs.ie

Web: www.ecowbs.ie